BEST PRACTICE SELECTION GUIDELINE

For cost effective and reliable underground Cable Duct systems, always consider 3 key selection factors – reliability, productivity and quality.

| BEST PRACTICE CABLE DUCT SELECTION CRITERIA | CALIBRE® Trench |

|---|---|

| RELIABILITY & DURABILITY | |

| Designed for 100+ years performance (buried in service) |  |

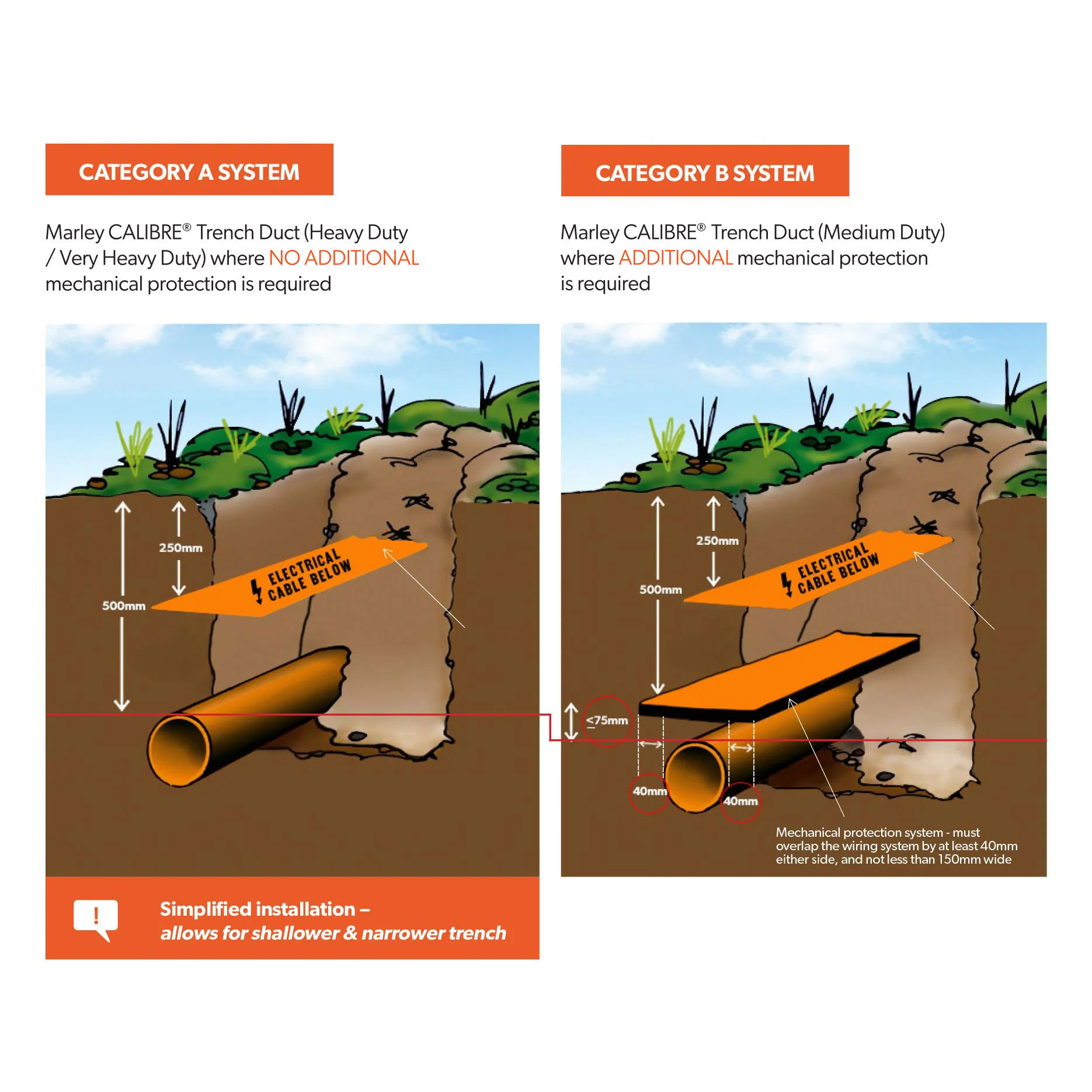

| Category A Underground Wiring Rules |  |

| Very Heavy Duty |  |

| Heavy Duty |  |

| Category B Underground Wiring Rules |  |

| Medium Duty |

(Extra mechanical protection required) |

| In-service temperature (wide range) | -15/60 |

| PRODUCTIVITY – INSTALLATION & BURIAL | |

| Application to suit project / site / economic parameters |

|

| Ease of handling / transport |

|

Ease of service identification

|

|

| Fittings range | Fabricated bends (duty, angle, radius) |

| Joining | PVC Solvent, PE Electrofusion, PE Compression fittings |

| QUALITY & COMPLIANCE | |

| Environmental | BEP (PVC applicable) |

| 100% Recyclable |  |

| Manufacturing standard – electrical specific AS/NZS 61386 |  |

| 3rd Party verification |  |

| Tech and sales support |  |

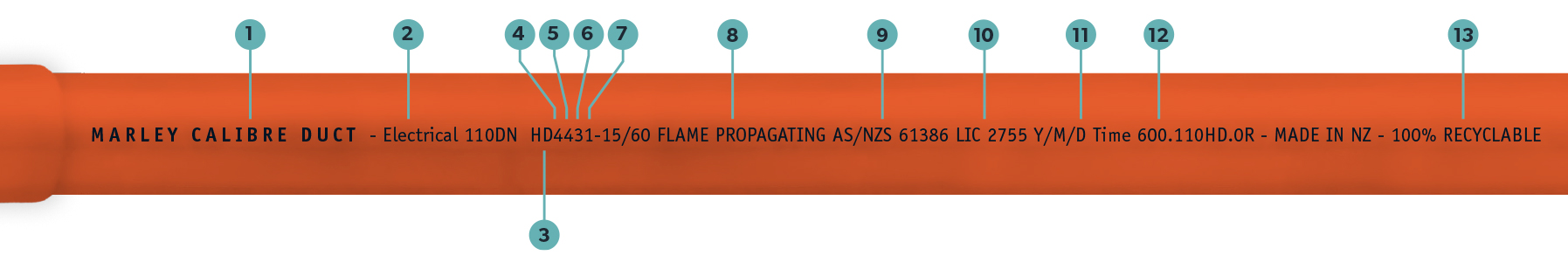

Product Authenticity

- Manufacturer and/or brand name identification

- Designed specifically to protect electrical wiring

- Classification Rating

(VHD = Very Heavy Duty)

(HD = Heavy Duty)

(MD = Medium Duty) - Compression Duty / Ring Stiffness Rating

(Rating 5 = Very Heavy Duty)

(Rating 4 = Heavy Duty)

(Rating 3 = Medium Duty) - Impact Duty Rating

(Rating 5 = Very Heavy Duty)

(Rating 4 = Heavy Duty)

(Rating 3 =Medium Duty) - Minimum Service Temperature rating (Rating 3 = -15˚c)

- Maximum Service Temperature rating (Rating 1 = 60˚c)

- Resistance to burning (PE duct only = flame propagating)

- Cable Duct manufacturing standard

- 3rd party Licence Verification for the specific manufacturing site

- Exact date and time of manufacture

- Marley item code for easy tracking

PVC = 700 Series

PE = 600 Series - Recyclability

PRODUCT SPECIFICATION

SIZE |

|

|---|---|

| DIAMETER (mm) | 32, 40, 50, 65, 80, 100, 150,(PE = 140/160) |

| LENGTH (m) | 6, (PE = 12) |

MATERIAL |

|

| COLOUR | Orange, Green, White, Red |

| FORMULATION | uPVC Resin + modifiers |

| FINISH | Matte Finish |

TEMPERATURE |

|

| SERVICE TEMPERATURE RANGE | -15˚C to 60˚C |

| LINEAR CO EFFICIENT OF THERMAL EXPANSION | 7 X 10-5 m/(mK) |

FITTINGS |

|

| MARLEY COLOUR MATCH | Orange, Green, White |

| EXTENSIVE RANGE | Yes |

| JOINT | Solvent (SJ) Rubber Ring Joint (RRJ) |

| DUTY RATING | Very Heavy Duty (5531) Heavy Duty (4431) Medium Duty (3331) |

DURABILITY |

|

| Duty rating1 | Very Heavy Duty (5531) Heavy Duty (4431) Medium Duty (3331) Non-Duty Rated |

| Ring stiffness (SN) (when DN≥100) |

MD ≥ SN4 HD ≥ SN10 VHD ≥ SN25 |

| Resistance to burning | Non flame propagating |

| UV resistance3 | White Duct only |

| Chemical resistance | High2 |

COMPLIANCE |

|

| Manufacturing standard | AS/NZS 61386 AS/NZS 1260 |

| Environmental | BEP certified (PVC applicable) ISO 14001 |

| 3rd party verification | Manurewa: BV Lic. 2755 Horotiu: BV Lic. 2970 Tinwald: BV Lic. 2806 |

1 Duty rating varies by size and customer requirements, please contact Marley for more information

2 Avoid contact with ketones, esters, aromatic and chlorinated solvent

3 Cable ducting designed to be buried in service, unless stated otherwise