| MINI TRUNKING | MAXI TRUNKING | |

|---|---|---|

| Colours Available | White Brown |

Grey |

| Material | uPVC | uPVC |

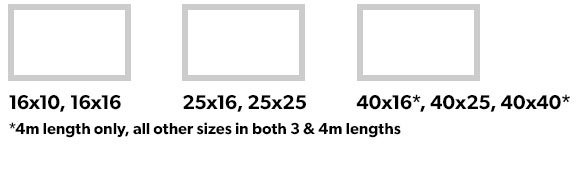

| Size Available*** | 16 – 40mm | 50 – 150mm |

| Duty Rating* | Light Duty | Heavy Duty |

| Impact Resistance* | Medium | High |

| Non-Flammable* | Yes | Yes |

| UV Resistant | White – high Brown – low |

Moderate |

| Temperature Range* | 0°C to +60°C | 0°C to +60°C |

| Comply with AS/NZS Standard |

4296 | 4296 |

| Chemical Resistance | High** | High** |

| Suitable Fittings | Yes | Yes |

* As per manufacturing standard AS/NZS 4296

** Avoid contact with ketones, esters, aromatic and chlorinated solvent

*** Range of depths available

MINI & MAXI TRUNKING

Marley trunking and fittings are manufactured from uPVC and are manufactured in accordance with AS/NZS 4296 Cable Trunking Systems.

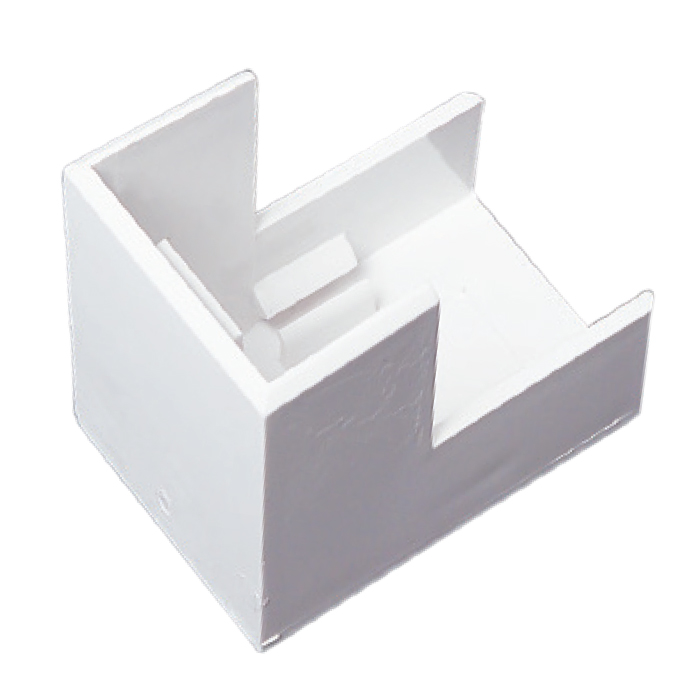

LIDS

Marley trunking features double-lock clip tops for security and accessibility.

To remove the lid; start with a peeling action from one end. Where lids are butted together, carefully insert a screw driver blade to enable an initial start to be made. Attempts to remove the lid in one motion along its length or forcing it with a tool under the edge will fail to remove the lid and may damage the edge of the trunking.

WEATHER DURABILITY

The grey and white Marley uPVC trunking range contains titanium dioxide to provide high UV performance.

N.B. Brown Marley trunking is designed for indoor use.

N.B. Grey Marley maxi trunking has a moderate UV performance.

Marley trunking may be painted using acrylic paints which will enhance the long term weatherability when installed outside.

INSTALLATION OF TRUNKING

All installation should be in accordance with the Electrical Regulations and AS/NZS 3000 Wiring Rules.

The following is a guide only:

- When planning the route to be taken, consider drops to sockets, switches and other fittings.

- Where angles and tees are required the trunking base ends should be mitre cut at 45° to provide a neat join.

- Fix the main body of the trunking by drilling through the base and screwing into position with flathead wood or metal screws. Oversize holes should be drilled to allow for expansion/ contraction and large washers used under the screw to provide suitable support.

- Fixings should be at maximum 500mm centres for mini trunking and 1000mm centres for maxi trunking. At low levels where trunking may be liable to impact or for uneven surfaces this should be reduced to 300mm centres.

- Once the base has been fixed the wiring can then be installed (hold in place by using short offcuts of lid).

- Cut lids 10mm shorter where fittings are to be used to allow fitting to snap over base.

- Once the wiring is in place, snap the lid into place by starting at one end, applying even pressure and work along the length (removing temporary wire supports) as you go. Then snap on lids of fittings.

- Allowances should be made for expansion/contraction. Do not push trunking hard against fittings. Allow a 7mm gap every 10 metres for every 10°C rise in temperature.

As per AS/NZS 3000* part 3.10.3.9 Cable trunking installations shall comply with the following:

- Covers shall be able to be opened, where practicable.

- Covers shall be continuous when passing through walls or floors.

- Cable trunking shall be accessible through its entire length.

- Cables installed in a trunking shall not rely on any readily removable cover for support.

- Non-hygroscopic trunking shall be used to enclose insulated, unsheathed conductors.

- Live parts of accessories mounted on cable trunking shall be arranged so that basic protection is provided, in accordance with Clause 1.5.4.