HOW TO SELECT PERFORMANCE BASED CONDUIT

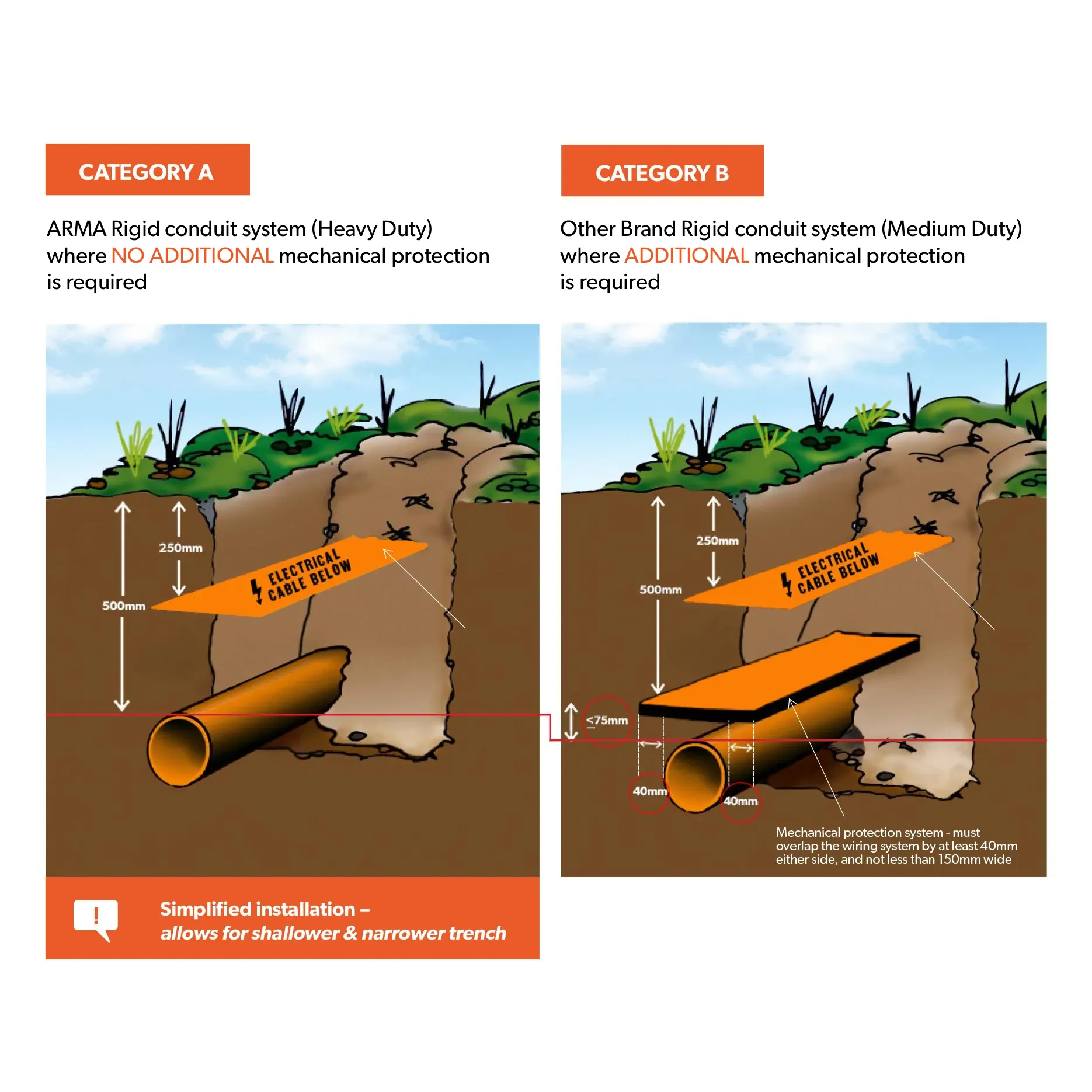

As a craftsman, achieving best practice performance and compliance for all your electrical cable management work is important. With the introduction of the AS/NZS 3000:2018 Wiring Regulations, use this 3 point guide for selecting electrical conduit.

Not all products are made the same

KEY SELECTION FACTORS

› Performance

› Heavy Duty Classification

› Compliance

| BEST PRACTICE CONDUIT FEATURES | MARLEY ARMA® |

|---|---|

| 1. DURABILITY | |

|

Mechanical Protection

|

|

|

HD4431 |

|

Service Temperature

|

-15˚C to 60 |

| 2. CRAFTMANSHIP | |

|

Material Finish

|

Gloss finish |

|

Fittings

|

|

|

Quality of cut

|

|

| 3. ASSURANCE | |

|

|

Product Authenticity

Not all brands of rigid conduit in the market perform to the same level.

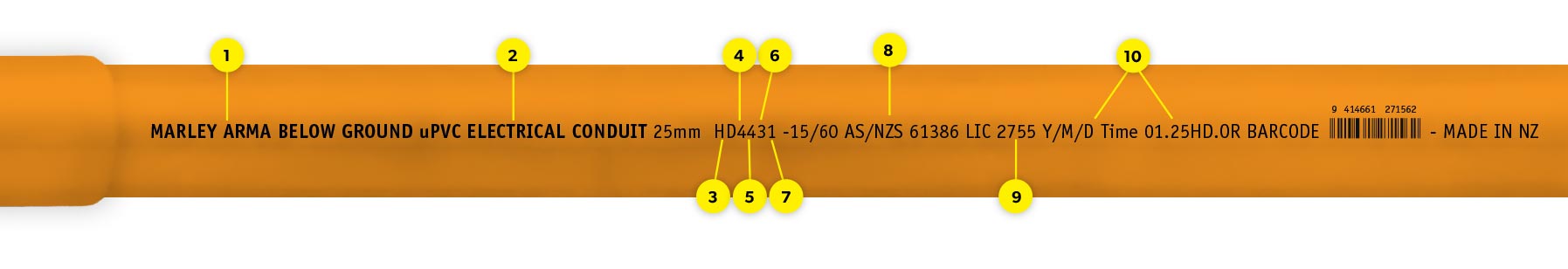

For proof of intended performance, check the mandatory print requirements that are marked on the conduit.

1. Manufacturer and/or brand name identification

2. Designed specifically to protect electrical wiring

3. Classification Rating

4. Compression Duty Rating (Rating 4 = Heavy Duty)

5. Impact Duty Rating (Rating 4 = Heavy Duty)

6. Minimum Service Temperature rating (Rating 3 = -15˚c)

7. Maximum Service Temperature rating (Rating 1 = 60˚c)

8. New Manufacturing Standard

9. 3rd party License Verification for the specific manufacturing site

10. Exact date and time of manufacture and Marley item code for easy tracking

If it’s not 4431 ask why not?

PRODUCT SNAPSHOT

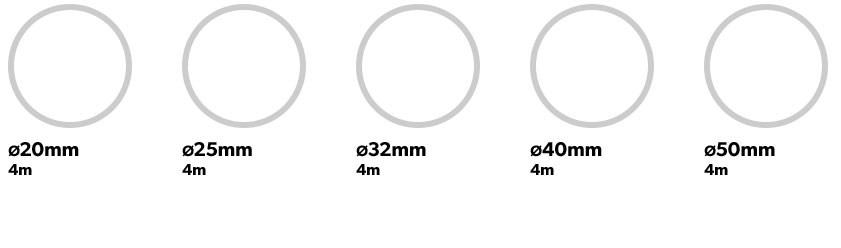

SIZE |

|

|---|---|

| DIAMETER (mm) | 20, 25, 32, 40, 50 |

| LENGTH (m) | 4 |

MATERIAL |

|

| COLOUR | Orange |

| FORMULATION | uPVC Resin + modifiers |

| FINISH | High Gloss |

TEMPERATURE |

|

| SERVICE TEMPERATURE RANGE | -15˚C to 60˚C |

| LINEAR CO EFFICIENT OF THERMAL EXPANSION | 7 x 10-5 m/(m K) |

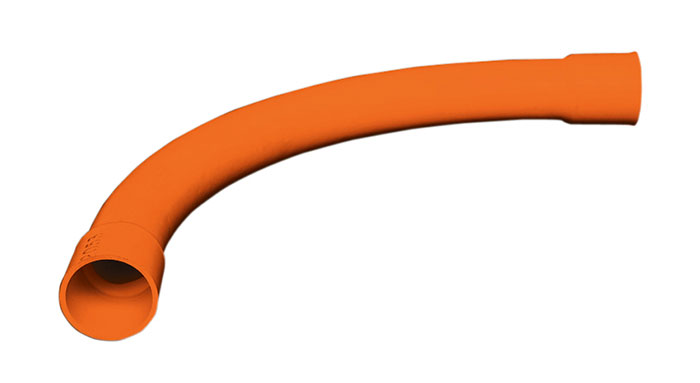

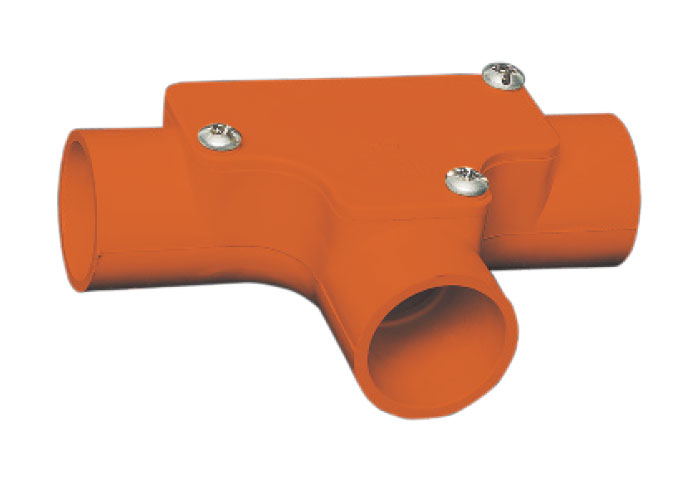

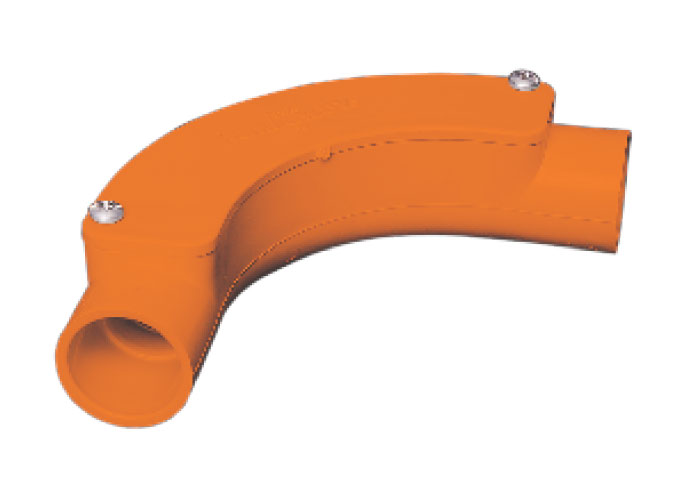

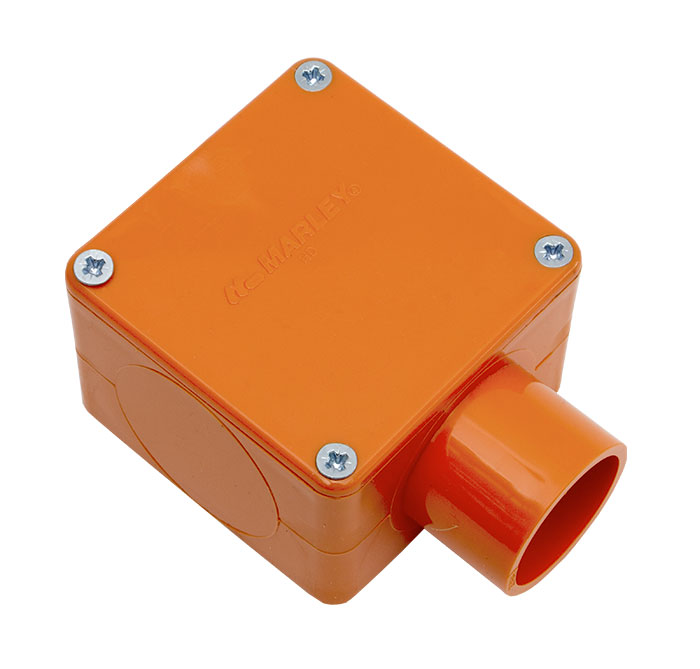

FITTINGS |

|

| MARLEY COLOUR MATCH | Yes |

| EXTENSIVE RANGE | Yes |

| SOLVENT JOINT | Yes |

| DUTY RATING | Heavy Duty 4431 |

DURABILITY |

|

| BUILDING CODE | NZBC B2 (Interior or concealed applications) |

| DUTY RATING | Heavy Duty 4431 |

| COMPRESSION RESISTANCE | HD – Rating 4 |

| IMPACT RESISTANCE | HD – Rating 4 |

| RESISTANCE TO BURNING (AS/NZS 61386) | Non flame propagating |

| UV RESISTANCE | No |

| CHEMICAL RESISTANCE | High2 |

COMPLIANCE |

|

| MANUFACTURING STANDARD | AS/NZS 61386 |

| ENVIRONMENTAL ACCREDITATION | BEP Certified |

| ISO 14001 | BEP Certified |

| 3RD PARTY VERIFICATION | BV Lic. 2755 |

1 Meets the requirements of AS/NZS5033 – Installation & Safety Requirements for Photovoltaic (PV) Arrays

2 Avoid contact with ketones, esters, aromatic and chlorinated solvents